Solving Assembly Interference in the Audio Equipment Industry

-How our ultra-low head screw “310Slim” resolved a critical design issue

【1】Customer Profile

Industry: Audio Equipment Manufacturer (Japan)

Application: Audio Mixer Console

This is a success story of globally renowned manufacturer of electronic musical instruments and professional audio equipment.

The company was developing a new audio mixer console intended for both live performance and studio use.

As the product was designed for frequent hands-on operation, ensuring a smooth and snag-free surface on the mixer console body was essential.

So they were looking for a new fastening solution that would improve both functionality and design.

【2】Challenges (Before)

The protruding screw heads prevent smooth operation for the user.

Accurate countersinking is required and need extra workload.

Since the screws were installed on the visible surface of the product, even slight protrusions affected the overall appearance.

Maintaining a clean, flush finish was essential for both aesthetic and functional reasons.

However, achieving a flat surface required precise countersinking and strict assembly control.

Any misalignment or tool marks around the screw heads were immediately noticeable to users.

These issues made it difficult to meet Roland’s high design standards and increased production complexity.

【3】Proposal

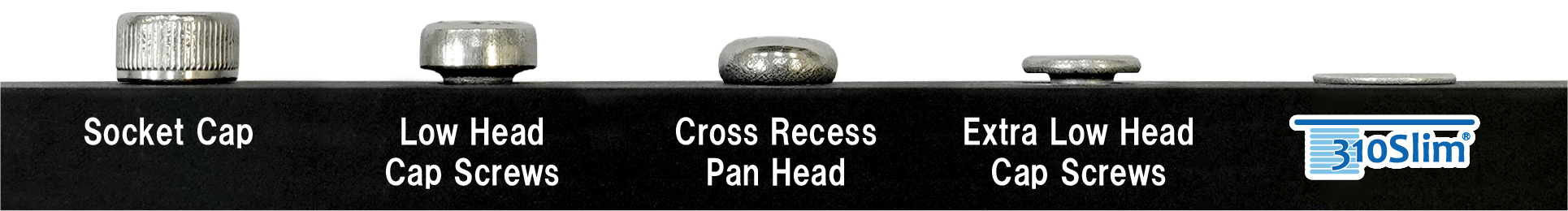

Proposed our ultra-low head screw “310Slim”

With its exceptionally low-profile head, it reduces interference and enhances both operability and appearance.

The screw enables smooth surface transitions, minimizing the risk of snagging or discomfort during use.

It also offers reliable fastening strength while maintaining a sleek, compact design.

Ideal for applications where user interaction and product aesthetics are critical.

Stainless A2 Black

【4】Results (After)

-Countersinking was no longer required, reducing machining steps.

-The improved aesthetics enhanced the overall design quality of the product.

By eliminating the need for countersinking required for flat head screws, the machining process was simplified, leading to reductions in both labor and cost.

Additionally, the screw head is barely noticeable, giving the product a more refined and sophisticated appearance.

As a result, it became possible to achieve high-quality product design that balances both functionality and aesthetics.

【5】Related Products

▶ View 310Slim product page

▶ Learn more about TRF security screws

【6】Customer Feedback

“This improvement has greatly enhanced user satisfaction.”

“It has created a competitive advantage in design and contributed to improving the brand image.”

“The manufacturing process has become more efficient, resulting in successful cost reductions.”

【7】Call to Action

👉 Facing a similar challenge? Contact us today