I have no idea what to start…

The screws will definitely come loose.

If you continue to rely on vague knowledge when designing, you may end up with serious accidents or complaints.

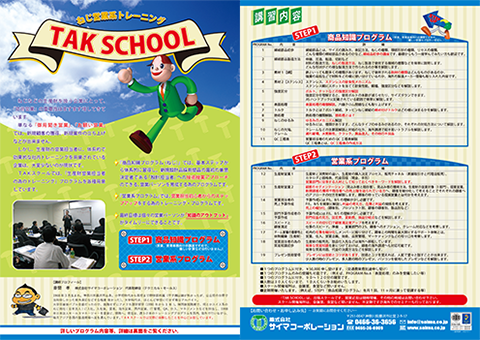

Why don’t you eliminate your worries at once at Saima’s TAK School?

I will mainly talk about what I have actually experienced.

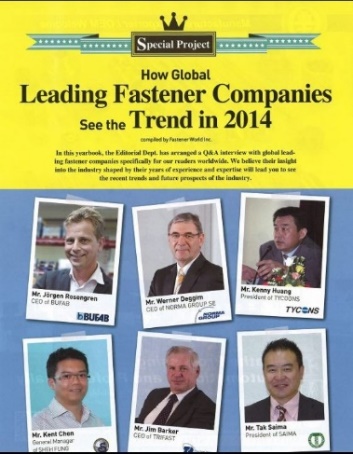

“TAK SAIMA” is a super professional who has been traveling all over the world solving screw problems for over 30 years.

Selected as a leading fastener company.

Fastener World Magazine

Top 2 popular screw seminars!

Torque Curve Analysis Seminar

- Wondering how to calculate tightening torque for tapping screws…

- What is “torque” anyway?

- I really wonder if this torque is enough…

Explanations will be provided through experiments using a torque analyzer.

Screw Loosening Seminar

- A screw came loose and caused a major complaint…

- I’m managing the torque, but it’s coming loose…

The screws will definitely come loose. Know the causes and take measures to prevent loosening in advance.

This section describes the types of screw loosening and effective countermeasures for each.

| No. | Contents | Details |

|---|---|---|

| 1 |  Fastening Components Elementary Fastening Components Elementary | This is a lecture on the elementary of fastening parts. Welcome those who would like to learn from the basics again. |

| 2 | Fastening parts manufacturing method | Wire drawing, heading, rolling, cutting, screw manufacturing methods, etc. |

| 3 | Material 1 [Steel] | About the types of steel materials. This content also includes information on foreign manufacturers. |

| 4 | Material 2 [Stainless steel] | Mechanism of corrosion resistance of stainless steel. |

| 5 | Strength class | Explanation of strength classifications of bolts, nuts, etc. Understanding the strength classifications allows you to reduce the number of bolts and their size. |

| 6 | Surface Finishing | Explanation of surface Finishing types. Hexavalent chromium problem is also covered. |

| 7 |  Torque Torque | This section explains how tightening torque can be determined. |

| 8 | Heat treatment | Explanation of types of heat treatment. What is heat treatment? |

| 9 |  Looseness of a screw Looseness of a screw | Explanation of the mechanism of loosening. Explanation of the various types of loosening and how to deal with them. |

| 10 | Screw defects, complaints | Delayed fracture, hydrogen embrittlement, cracks, foreign material contamination, and other problems that are likely to occur with defective products and overseas procurement. |

| 11 | QC Process Chart | QC process chart explanation and QC process chart creation method for sales representatives. |

[Product Programs] are also available. Please feel free to contact us.

Duration of Screw Seminar

90 minutes / 1 program

Seminar Fee

Please contact us.

Venue

Meeting room, cafeteria, or other space provided by your company, or online (zoom).

How to apply

1. Please send an e-mail to the reception desk with the subject line “Seminar request” and the necessary items below.

■Required fields■

-Program name

-Desired date and time

-Desired location

-Number of people expected to attend

2. We will send you an email confirming that your application has been received.

Based on customer request

-text in advance

-zoom link

-ID

-Passcode

We will send you above in advance.

3. Conducting seminars (on the day)

-We will hold a 90-minute course based on the text.

-There will be time for questions at the end of the lecture, so please feel free to ask any questions.

What’s important is

Let’s acquire the correct knowledge now!

Click here to apply for the seminar

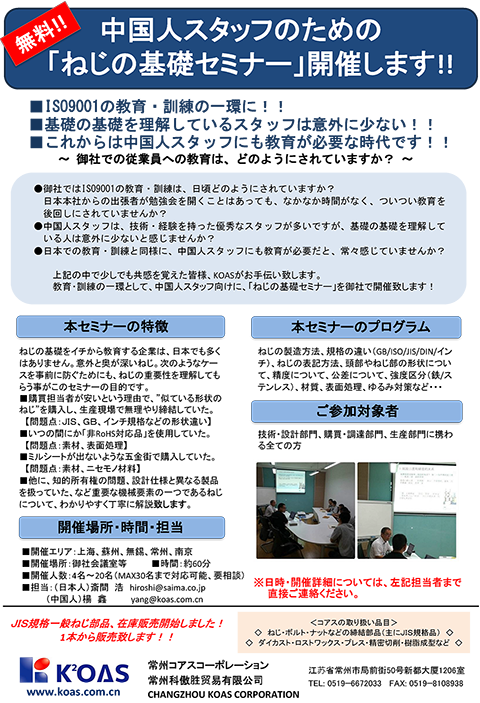

“Screw Basics Seminar” for Chinese staff too!

“Screw Basics Seminar” for Chinese staff too!

No time to hold a study session!

Few people understand the basics of screws!

same education to Chinese staff as we do in Japan!

Saima Corporation and Changzhou KOAS will help you!

Please use it as part of your ISO9001 education!