Solve your tapping screw tightening torque problems!

Not sure if using the same tapping screws is O.K…

Don’t know how to eliminate cracks…

Want to know the proper tightening torque…

The counterpart material has changed but not sure the proper pilot hole size…

The design and prototyping went well, but after entering mass production, a problem occurred!

We can solve your problems related to tightening torque with PC Torque Analyzer!

- Simulation of the best match of the three major factors when designing a tapping screw: “hole diameter” + “tightening torque” + “type of tapping screws” can be performed.

- The actual fastening characteristics to the workpiece are displayed in a graph.

Saima provides torque analysis services using a torque analyzer.

PC Torque Analyzer -Advantages of Measuring Screw Tightening Torque

Aim to supply the stable quality product

The optimum torque value for tightening screws differs depending on the shape and material.

By tightening screws with the proper torque value, we can eliminate defective products and ensure a stable supply.

Torque control is essential for tapping fasteners on plastic products

This is not so much of a problem when the counterpart material is steel, but it is not the case with plastic.

If the tightening torque is not appropriate, over-tightening can cause cracks.

Also, loosening can be caused by not firm tightening which also cause unexpected injury.

Torque testing on actual products are expected to reduce the defect rate.

Best for choosing self-tapping screws

We will propose the optimum values for the three major factors when designing tapping screws: “hole diameter,” and “type of tapping screws.

You can also try Saima’s original “Non-sert” tapping screws for plastic.

Good for the maintenance on Plastic product

General tapping screws are difficult to use repeatedly.

However, by using the optimum hole diameter + optimum tightening torque + “Non-sert” tapping screws for plastic, they can be used repeatedly.

There is no need to replace to the new Non-sert tapping screw.

Click here for details of “Nonsert” tapping screws for plastic.

Click here for more infomation about the torque test.↓

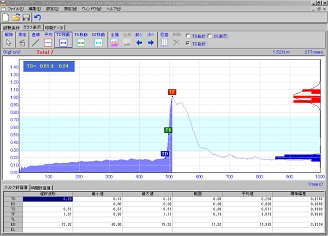

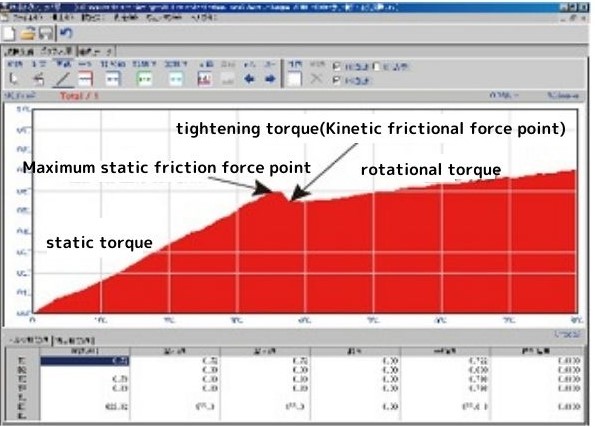

Tightening torque test with torque analyzer

The torque characteristics of tapping screws can be checked on a graph

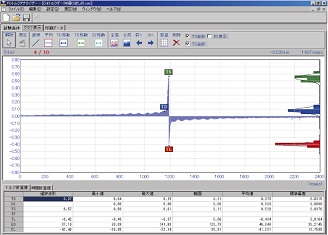

Returning Torque Test

Returning torque measurement of screw loosening

To perform a screw loosening test, returning torque is displayed on a graph at a slow rotation speed.

Loosening characteristics of screw are analyzed by detecting the return rotational starting torque: TL(Torque of Loosening).

TL can be displayed as a histogram with normal distribution curve as well as TD and TF.

The figure shows the loosening torque curve at a low speed of 10 rotation per minute.

Repeat test

Automatic alternating switching between tightening torque test and Return torque test

Tapping screws are considered unsuitable for repeated use in maintenance.

The number of times a tapping screw can be repeatedly used can be measured by automatically switching between the tightening torque test and the reversing test.

Retightening Torque Measurement

Tightening torque is retorqued, and torque is analyzed and measured graphically.

By measuring the actual torque at which a screw is being tightened, the maximum static and dynamic frictional force points at which the screw will start rotating again can be found.

This is a useful function for measuring creep (shaft force reduction).

Retightening torque curve at low speed of 6 rotation per minute

We can go set up and lecture you how to use at the time of the purchase!!