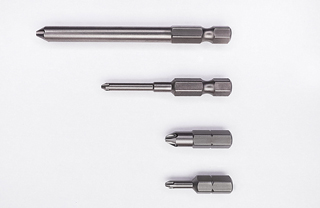

Features

- No metal insert required. Cost reduction.

- Low torque driving, low stress for plastic.

- “non-sert” Hole Size

- 4th Generation Thread forming Tapping Screw for Thermoplastic

RoHS Directive Compliant Product

RoHS Directive Compliant Product

non-sert

Pan Head non-sert

Steel 3Cr

Pan Head non-sert

Steel 3Cr

Pan Head non-sert

Stainless A2

Pan Head non-sert

Steel Black Ni

Flat Head non-sert

Steel 3Cr

Washer Head non-sert

Steel 3Cr

Binding Head non-sert

Steel 3Cr

310Slim non-sert

QuaStix non-sert

Self Tapping Screw for SANYO DENKI FAN

SY-non-sert is a self tapping screw developed with Sanyo Denki Co., Ltd., which apply SAN ACE cooling fan.

self tapping screw for

SANYO DENKI FAN

Steel 3Cr

self tapping screw for

SANYO DENKI FAN

Steel 3Cr Black

self tapping screw for

SANYO DENKI FAN

Steel 3Cr

self tapping screw for

SANYO DENKI FAN

Steel 3Cr Black

Merits of changing to non-sert

★No metal insert required. Cost reduction.

★Easy to recycle without metal insert.

★Less cracking.

★Repeatable on the same pilot hole.

★Low torque driving, low stress for plastic.

APPLICATION

San Ace Cooling Fan

Gas Alarm

Microphone Capsule