Reducing Weight with Screws

Among the screw materials, it is better to reduce the weight with magnesium alloy or titanium screws.

On the other hand, I think there are many people who have given up due to cost problems and convenience.

◆ 310Slim® is a screw that have Rliminated Waste

It’s easy to reduce weight because it’s iron or stainless steel A2

310Slim® is made of the same iron and stainless steel as the materials used for general screws, so it is not a difficult material to process like titanium.

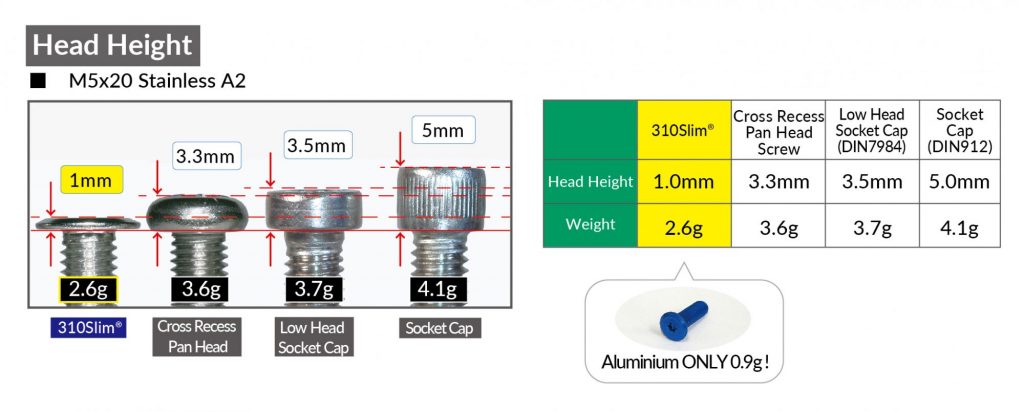

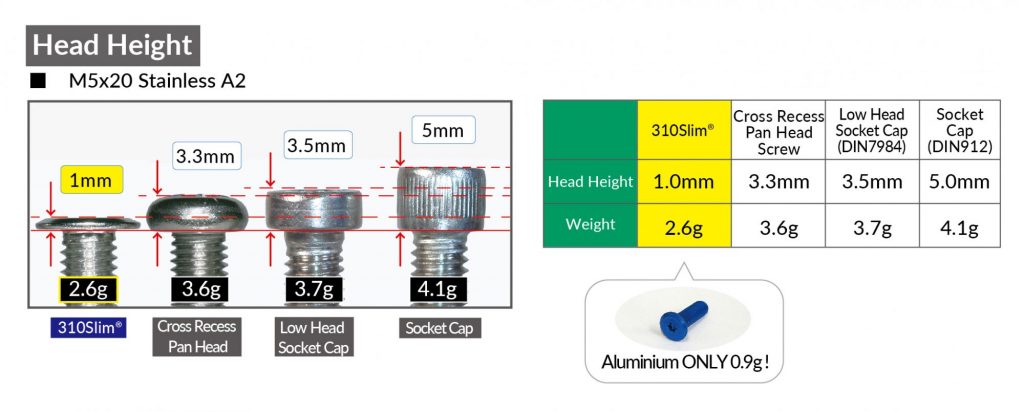

It is a screw that can reduce weight by eliminating waste of the head.

Those who want to quickly lighten even 1g, this screw is a must-use for those who want to eliminate protrusions.

(5μm+)

(Cu+Ni)

(Cu+Ni)

◆ Lighter Aluminum Screws are Also Available!

It weighs about 1/3 of iron and stainless steel A2!

Aluminum screws that are lightweight and have little protrusion are also available.

Color anodized screws are also usually in stock, so they can be shipped on the same day.

How Much Lighter Will It Be?! Weight Comparison

Comparison of the total weight of screws M5x10 10pcs. each.

| Socket Cap Steel, Stainless A2  | Cross Recess Pan Head Steel, StainlessA2  | 310Slim® StainlessA2  | 310Slim® Aluminum  |

| 31g | 23.5g | 15.1g | 5.1g |

Comparing 10 hexagon socket socket socket bolts (iron and sten) with 10 310Slim® sten, it is about 15.9g lighter

It is equivalent to about two “500 yen coins”.

Comparing 10 hexagon socket bolts (iron and stain) with 10 310Slim® aluminum, it is about 25.9g lighter.

It is equivalent to about one “AA battery”.

Just by changing 10 machine screws to 310Slim®, you can expect to reduce the weight by this much.

Click here for a simple weight comparison⇒

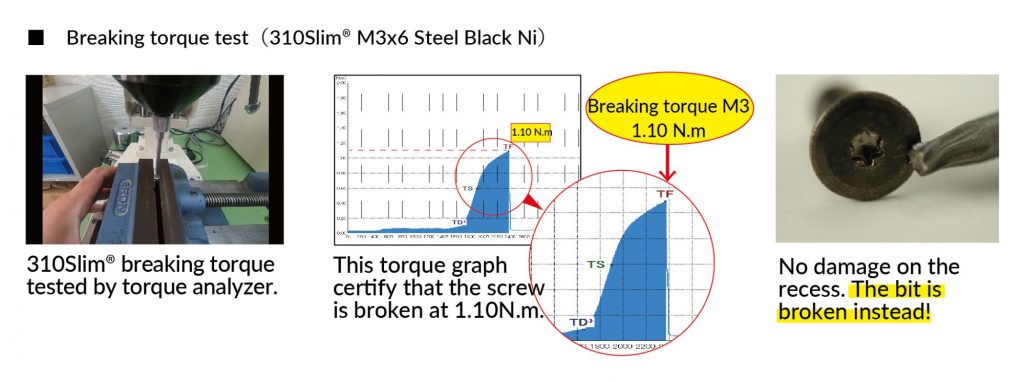

Even if the weight is reduced, the strength of the screw remains the same

Because the 310Slim® is made with the same strength as a machine screw,

There is no problem if it is tightened with the same torque as a machine screw.

Some people are worried about strength if the weight is reduced, but there is no problem.

Aluminum screws are about half the strength, but screws made of iron or stainless steel A2

There is no problem if it is tightened with the same torque as machine screws sold in general.

310Slim® Iron / StainlessA2 M2 ~ M6

| M2 | M2.6 | M3 | M4 | M5 | M6 | |

|---|---|---|---|---|---|---|

| Machine screws (strength category 4.8) Standard tightening torque* | 0.17 | 0.35 | 0.63 | 1.48 | 2.98 | 5.07 |

| Minimum breaking torque of the 310Slim® | 0.4 | 0.5 | 0.95 | 2.3 | 4.0 | 10.0 |

* Reprinted from Tohnichi Manufacturing Co., Ltd. Torque Handbook Vol.9 P.39

310Slim® Aluminum M3 ~ M6

| M3 | M4 | M5 | M6 | |

|---|---|---|---|---|

| Machine Screws (Aluminum, Brass, Copper) Standard tightening torque* | 0.31 | 0.74 | 1.49 | 2.55 |

| Minimum breaking torque of the 310Slim® | 0.45 | 1.0 | 1.7 | 3.3 |

* Reprinted from Tohnichi Manufacturing Co., Ltd. Torque Handbook Vol.9 P.39

Lightweight screw 310Slim® is also effective in saving space

It is also ideal for saving space because there is no protrusion of the head and securing clearance.

It’s lightweight, so it’s important that it’s hard to come out.

There is no protrusion on the head, so it will be difficult if you come out.

Even if you change the screw to reduce weight, the screw cam-out will cause.

There is no point in not being able to maintain it.

310Slim® is hard to come out.

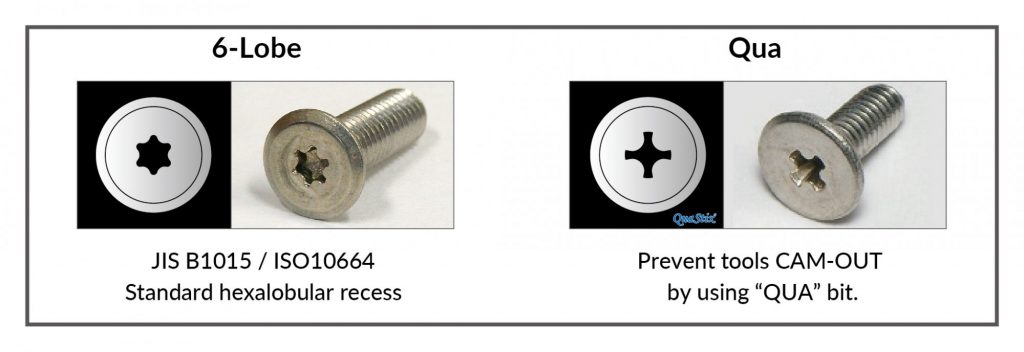

There are two types of 6-lobe and qua*(cross hole).

*It can also be used with commercially available cross screwdrivers and bits.

Click here for details that are difficult to cam-out⇒